Pipeline Ancillaries

Air Vents

Many industrial processes involve the removal of air/gas from a pressurized liquid. Armstrong air vents are ideally suited for this purpose. The float-operated design means the vents can instantly and automatically adjust to variations in gas flow and pressure. The air vents can handle gas removal from liquids with specific gravities as low as 0.40 and pressure to 2,700 psi (186 bar). Armstrong air vents are available in a wide variety of sizes, end connections, and construction materials.

Liquid Drainers

Armstrong’s Float-Operated Drain Traps are designed for draining heavy liquids from gases or light liquids (dual gravity drainers).

These liquid drainers can operate to 1800 psig / 255 barg or specific gravity down to 0.40.

Safety Valves

A complete range of pressure safety and relief valves for

- Steam

- Compressed air

- Hygienic applications

- Special or technical gasses

- Aggressive media

Globe Valves

EBSV Bellow sealed valves have been designed in a very compact settlement and provide perfect flow control. They are manufactured in different materials suitable for various applications including steam and industrial water etc

Non-return Valves

Check valves are fluid control devices that restrict the flow of media in a piping system to one direction. This broadly defined check valve function plays different roles in various industries. Also known as non-return valves, one-way valves, or backflow preventers, check valves prevent flowing media from flowing back upstream.

Separators and Filters

Armstrong DS Series in-line (drain) separators separate condensate efficiently by using the centrifugal force of steam or air created by introducing it into a specifically shaped path. Because of the simple structure of the drain separators, pressure loss is minimized, enabling clean, dry steam or air to be fed to equipment.

Sight Glasses

A sight glass or water gauge is a type of level sensor, a transparent tube through which the operator of a tank or boiler can observe the level of liquid contained within

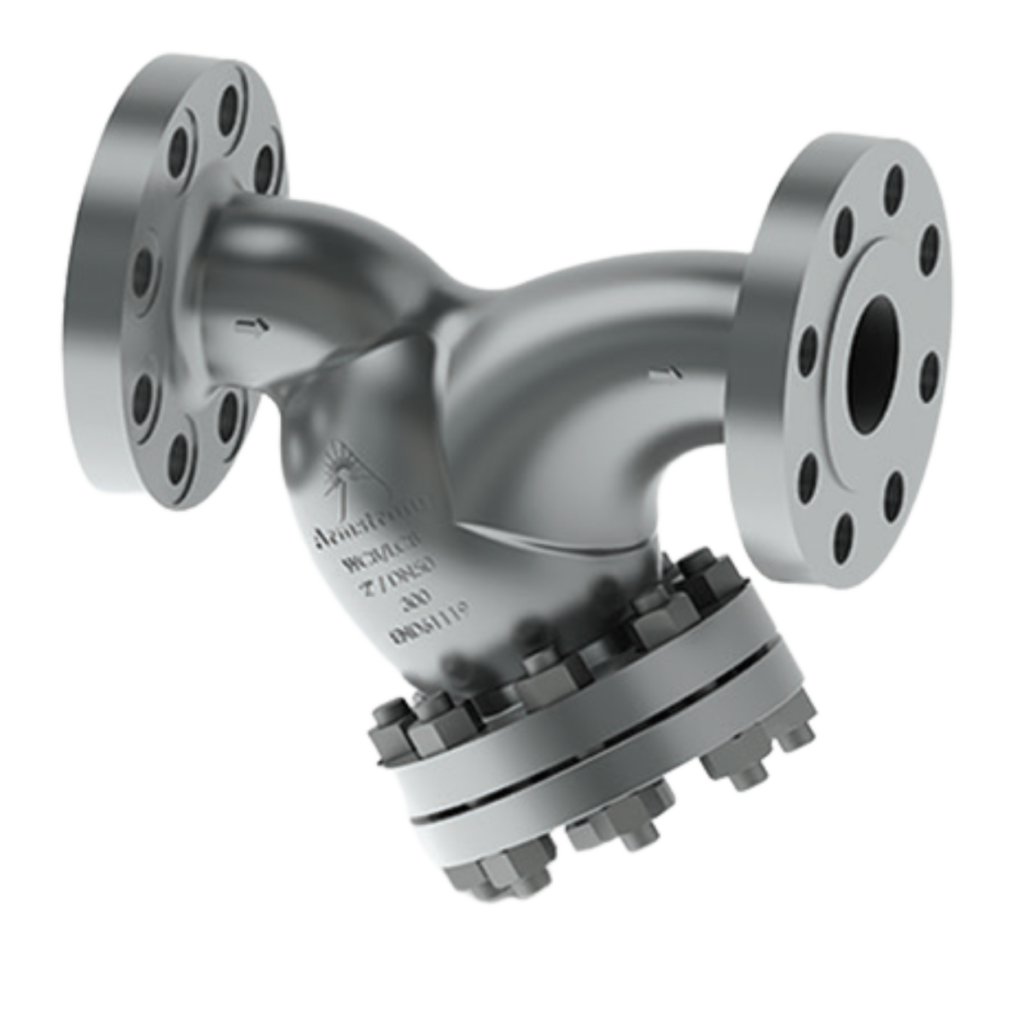

Stainers

Strainers feature screen chambers that won’t leak or crush. Both ends of the chambers are precisely machined. This means perfectly round and smooth seating surfaces, as well as a fixed chamber length. Since the screen seats snugly on the machined surface, no particle bigger than the screen opening can escape around the end of the screen.

Pressure & Temperature Indicators (Gauges) and Accessories

– Bourdon Tube and Capsule Element Pressure Gauges- Digital Pressure Gauges

– Pressure Gauges with Diaphragm Seal

– Differential Pressure Gauges

– Pressure Gauge Cocks and Manifolds

– Pressure Gauge Siphon Tubes

– Bimetal Temperature Gauges

– Expansion Temperature Gauges with Capillaries

– Glass Thermometers